There are a number of frame issues to keep an eye out for that could cause problems

during the stretching process. Knowing what to look for can save both time and money.

The solutions are generally quick and easy. The worst offender is a warped frame. Sharp

edges and heavy spots of old glue can also cause problems. It’s always a good idea to

inspect your frames before the stretching process. Once you determine your frame is in

good condition, bring the screen up to tension and make sure there is good contact

between the mesh and the frame while gluing.

Warped Frame

A warped frame has a whole host of problems all its own, from uneven tension,

difficulty getting an even emulsion coat and difficulty registering on press to potentially

breaking the glass in your exposure unit (single points of contact). Roller frames are a bit

easier to correct by pushing or pulling the offending corner. A warped stretch and glue

frame is caused by either a manufacturing defect or metal fatigue. In either event, it’s

difficult to correct. If it’s a new frame, contact the supplier. If it’s an older frame,

consider replacing.

Sharp Edges

Sharp edges can develop from rough handling throughout the process or by not

removing the glue properly during reclaim. Use a piece of cloth to avoid injury and drag

it along the edges of the frame that will be in contact with the mesh. If the cloth pulls,

remove the burr with a file or sand paper.

Glue Build Up

A common practice in reclaiming a frame is to leave the previous layer of glue. In

many cases it provides a better surface to glue to than the original aluminum surface. Be

careful not to let the glue build up become too heavy. With many types of glue, parts of

the thick layer will break off with the mesh during reclaim creating pockets on the glue

surface that will be hard to fill in.

Mesh/Frame Contact

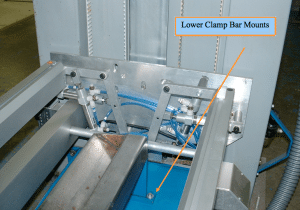

Most stretch and glue stretching systems these days allow you to stretch the mesh with

out contact to the frame until the desired tension is achieved. At that point the mesh is

lowered to the frame or the frame is raised to the mesh. Before gluing, inspect the

contact area by pushing down on the mesh along the inside edge of the frame. If the

contact is not good, you will physically see the mesh come into contact as you push

down. Providing the problem is not drastic, a simple solution is to use weights along the

inside edge. I prefer 1″ x 1″ x 12″ steel bar stock with all edges and corners rounded.

Place the weights approximately 2″ from the inside of the frame along the entire ID of the

frame.