There are a number of frame issues to keep an eye out for that could cause problems during the stretching process. Knowing what to look for can save both time and money. The solutions are generally quick and easy. The worst offender is a warped frame. Sharp edges and heavy spots of old glue can […]

Read MoreYou can visually see if there is a thicker deposit of emulsion in the corner of the screen by noticing the darker color. First, it is important to establish if the problem is consistent and happens on every screen or if the problem is random. If the problem is random, then quite possibly there is […]

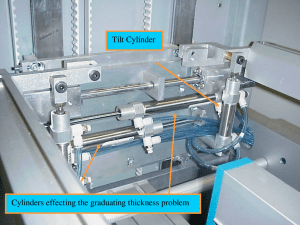

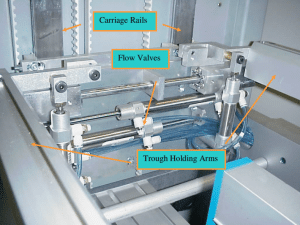

Read MoreOver time the coating machine’s carriage mechanisms, responsible for bring in the coating troughs into the screen, will fall out of calibration and need adjustment. Usually, the tell tale sign is a heavy deposit of emulsion along one side of the screen from the bottom to the top. There are generally two versions of the […]

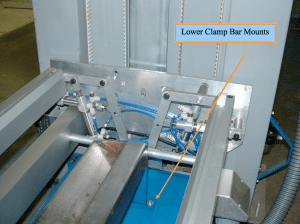

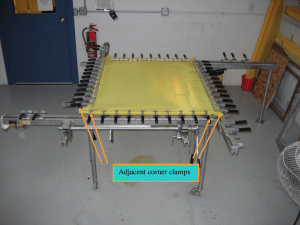

Read MoreThe general operating principle of a mechanical stretching system is four rails each containing individual stretching clamps that move along the rail as the screen is tensioned and the mesh elongates. Adjust the stretching system’s size To properly tension a screen, first adjust the stretching system’s size to accommodate the frame. Load the frame onto […]

Read MoreProper maintenance of a coating machine (and troughs for that matter) is a fairly simple and not a very time-consuming task in the grand scheme of things. Obvious, but not always followed, if it’s dirty, clean it. If it moves, grease it. If it leaks air, stop the leak. Poor edge quality (knicks) With coating […]

Read More

Thanks for stopping by

Prepress Resources.

Hi, I’m Chris LaGoy. I have 26 years of experience throughout North America repairing, servicing and installing prepress screen printing equipment. I hope you find my repair tips from the field helpful.

If you have a question, Get in Touch.

Wiring diagrams, schematics, exploded mechanical diagrams and more.